Product Details

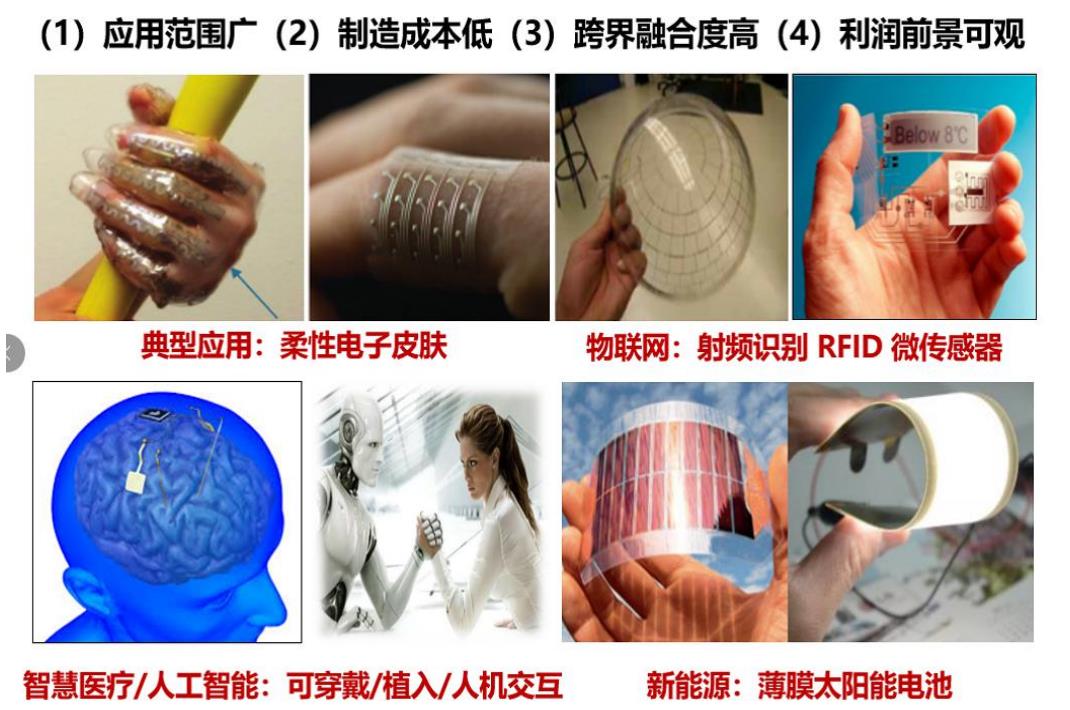

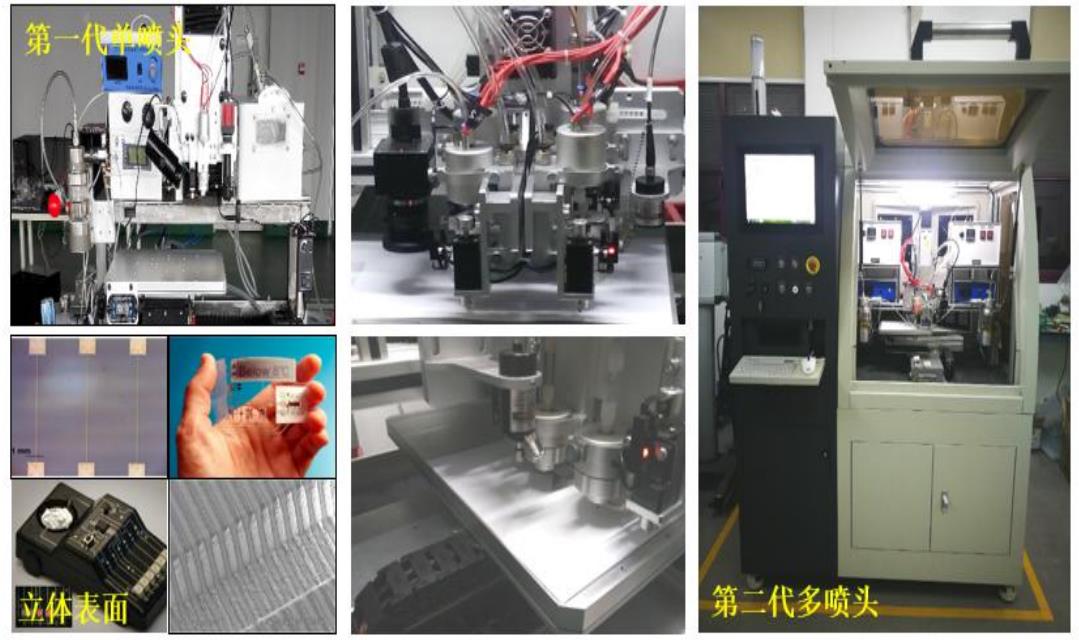

As a rapid additive manufacturing printing technology, flexible electronic micro-injection 3D printing technology has many advantages such as non-contact, high deposition accuracy, wide range of ink materials and controllable precision. It is becoming an ideal manufacturing technology for flexible circuit board, solar cell, thin film transistor, micro sensor, electronic skin and other precision electronic components. It can realize the additive manufacturing of many functional materials including metal, conductor, insulator and composite materials. Due to the non-contact mode and the height control between the nozzle and the substrate of 10 to 15mm, it can adapt to the printing of complex curved surface including curved surface. The multi-nozzle array structure can realize the printing and packaging of flexible electronic equipment at one time, which solves the problem of multi-process equipment in the traditional manufacturing process. The self-developed printing system can generate and process the line graphics generated by the user through the standard CAD software, and then transport the ink made of materials through the transport of nitrogen through the particle filter to the nozzle through the pneumatic atomization and ultrasonic physicalization, and then deposit on the surface of the substrate material after being constrained by the surrounding gas. After laser sintering and baking of the substrate, the droplet particles are bonded to improve its related electrochemical performance. Finally, the ultra-fine line width pattern with a line width of less than 10um can be generated on the surface of the substrate. The printing process can not only realize the automatic control of the process, but also through the machine vision system real-time monitoring of the printing process, can be printed in glass, ceramic, paper and a variety of materials surface complex structure, can be widely used in the surface spraying, micro structure, micro sensor, flexible electronics, new energy, optical manufacturing, biomedicine and other fields.

Technical Advantages:

printed material by the surrounding gas around inside the shower nozzle, on the one hand to avoid the jam problem, on the other hand put off print diameter of nozzle diameter dependence relationship;

between nozzle and substrate adopt non-contact structure, can realize adjustable height above the distance 10 mm print, to adapt to the complex substrate surface conditions;

nozzle array and a visual observation system is not only applicable for material mixing printing and can print progress monitoring at any time;

pneumatic system including nitrogen gas path system with vacuum pump gas path system used to produce lose send gas, nitrogen gas path system pneumatic nebulization, surrounding gas.

Technical Parameters:

Product type: INCH-AJP220A

Overall dimensions: 1400*900*1750mm

Feature print size: 220*220*100mm

Minimum print line width: 8μm

Minimum printing thickness: 500nm

Standard printing speed: 100mm/s

Machine vision systems: Industrial CCD cameras

Printing positioning accuracy: 0.005mm

Printing material optional: micro - nano suspension

Post-treatment: laser sintering /UV curing

Power supply rate: 220V/2Kw

Product Features:

Ultra-fine line-width Micro-injection flexible electronic 3D printing System (the first one in China/independently developed)