Product Details

SLM metal printing process features:

process simple, less processing process, short manufacturing cycle;

don't need traditional machining of cutting tool, fixture and mould;

compared with reduction of material processing method, the material utilization rate is high, the cost is low;

molding parts density is high, but close to 100%;

forming high accuracy and good mechanical properties, without being limited by the parts structure complexity.

Equipment performance advantages:

equipment adopts closed loop control, comprehensive monitoring and feedback, positioning accuracy of + / - 0.003 mm or less;

high mechanical precision, precision can reach 0.035 mm;

substrate feeding cylinder with active preheating function, and can greatly reduce the residual stress, decreases from von berg systeme deformation;

molding using pulsing vacuum atmosphere circulation system, greatly reduce the consumption of the shielding gas.

Technical Parameters:

Product model: INCH-SLM150

Molding size: 150mmX150mmX100mm

Powder thickness: 5-100um

Laser power: 200w

Scanning speed: 7000mm/ s

Positioning accuracy: ±0.003mm

Preheating temperature: 180°C

Oxygen content: 100ppm

Forming atmosphere: N2 or Ar protection

Gas consumption: 3L/ min equipped with soot recovery system

Forming materials: cobalt alloy, titanium alloy, tantalum alloy, stainless steel and other metals

Appearance size: 960mm*1300mm*1920mm(length × width × height)

Installation size: 3200mm*2500mm*2500mm(length * width * height)

Equipment weight: 800kg

Power supply: 220V 3Kw

Ambient temperature: 20-35°C

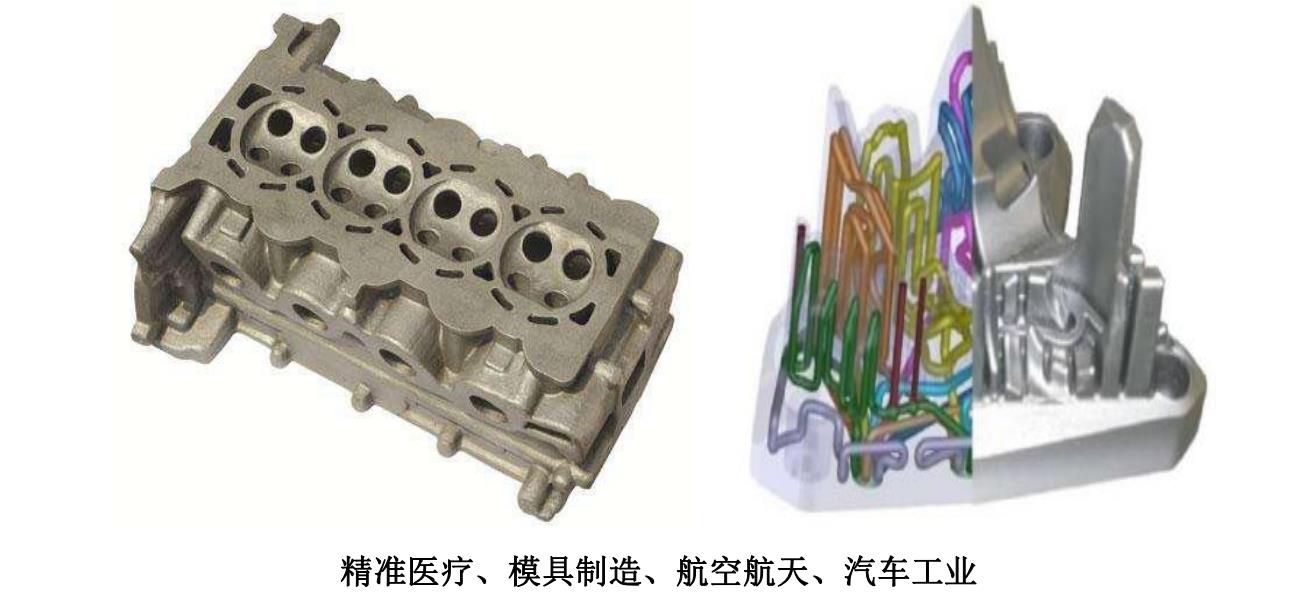

Application Field: